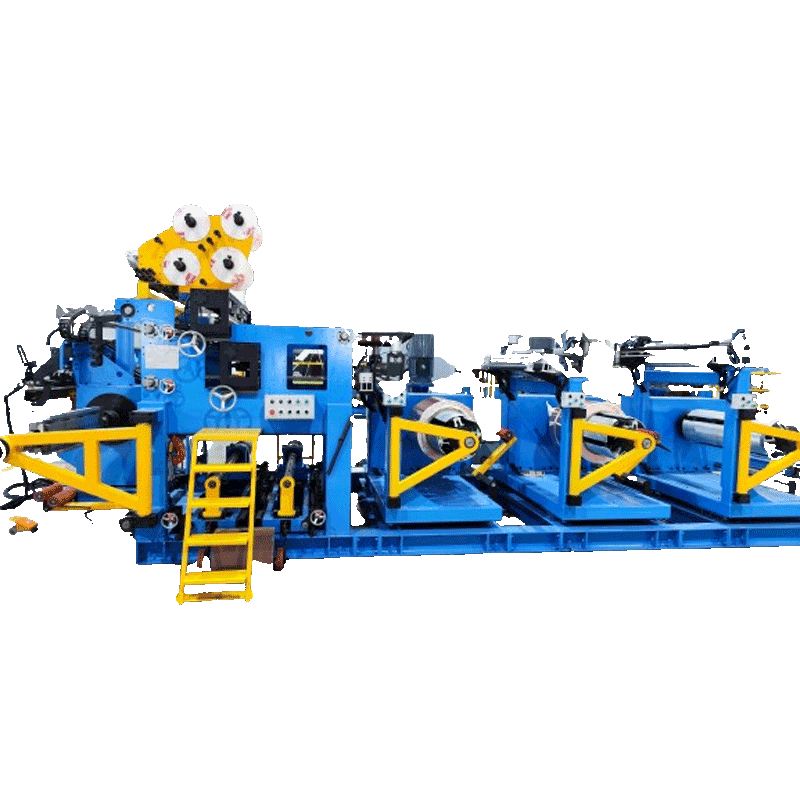

Ikhoyili yefoyile ye-LV isebenzisa ubukhulu obahlukeneyo bobhedu okanye ifoyile ye-aluminiyam njenge-conductor, i-band band ebanzi yohlobo lokugquma i-insulation njenge-insulation umaleko, ukujika-jika okupheleleyo kumatshini wokujija oluhlobo lwe-foil, ukwenza i-coil roll.

Esi sixhobo sinokusetyenziswa nakwi-coil winding efanayo kushishino lombane.

Umatshini wamkela indlela yokulawula i-PLC eneempawu zeqondo eliphezulu lokuzenzekelayo.

Ⅱ.Ukuqulunqwa kunye noMsebenzi weSixhobo

BR/III-1100 Three-Layer Foil Ukujija Machine iquka

1) Isixhobo se-foil de-coiling device 2) Isixhobo sokuvala i-winding 3) Isixhobo se-insulation decoiling

4) Iinqununu eziphambili zesakhelo 5) Isixhobo se-Welding 6) Ukuchithwa kunye nesixhobo sokucoca

I-7) Isixhobo sokusika i-8) Isixhobo sokukhupha i-insulation ekupheleni njl njl

III. IiParameters eziphambili zobuGcisa

| Sr# | INTO | INGCACISO |

| 1 | Ikhoyili | Uluhlu lokuqhubekekisa |

| 1.1 | Ubude be-axial | 250 ~ 1100 mm |

| 1.2 | Ubude be-axial (Bandakanya ukhokelo) | 400~1760 mm(kunye nelothe RH 16 intshi, LH 10inch) |

| 1.3 | Idayimitha yangaphandle (Max) | Φ1000 |

| 1.4 | Ifom yekhoyili | Round / cylindrical / uxande / coil ubunzima ≤2000KG |

| 1.5 | Ubude beziko | 850mm |

| 2 | Izinto zekhoyili | I-foil yobhedu, i-aluminium foil |

| 2.1 | Ububanzi | 250-1100 mm |

| 2.2 | Ukutyeba (Ubukhulu) (Ubukhulu bubonke) | Ifoyile yobhedu:0.3–2.5mm Ifoyile yeAluminiyam: 0.4 ~ 3mm |

| 2.3 | Ikhoyili ububanzi bangaphakathi | Φ400-500mm |

| 2.4 | Ikhoyili idayamitha yangaphandle (Max) | φ1000mm |

| De-coiler | Iiseti ezintathu ezizimeleyo |

| 3.1 | Ubude be-cylinder yokuthwala | 1150 mm |

| 3.2 | Ukwandiswa koluhlu lwe-cylinder yokuthwala | Φ380~φ520 |

| 3.3 | Ukuthwala umthamo (Max) | 2000KG |

| 3.4 | Amandla okwandisa (Umbane) | 0~15000N Ulwandiso lwamandla olungena nyathelo olulungelelanisiweyo |

| 3.5 | Indlela yokulungiswa kwe-offset | Imanuwali/Iyazenzekela |

| Umatshini womoya |

|

| 4.1 | Isantya somoya | 0 ~20 rpm |

| 4.2 | Itorque esebenzayo (Ubukhulu) | ≥ 8000N·M |

| 4.3 | Amandla omoya | 20-30 KW |

| 4.4 | Indlela yokulawula isantya | Uguqulo lwamaxesha olawulo lwesantya olungenanyathelo |

| 4.5 | Ishafu yomoya | 50*90mm |

| 5 | Isixhobo sokuwelda |

|

| 5.1 | Imo yeWelding | TIG |

| 5.2 | Ukuqhuba ibha welding ubukhulu | ≤ 20mm |

| 5.3 | Isantya sokuwelda | Ulawulo lwesantya esizenzekelayo 0~1m/min Ummiselo wesantya esingenanyathelo |

| 6 | Isixhobo sokusika |

|

| 6.1 | Ifom yokusika | I-Lead Screw Cutting Disc |

| 6.2 | Ukusika isantya | 1.5 m / min |

| 6.3 | Ukusika ubude | 1150mm |

| 7. | Umaleko wokugqumakhululaisixhobo | |

| 7.1 | I-layer insulation efakwe kwishaft | 2 iiseti |

| 7.2 | I-Layer insulation roll idayamitha yangaphandle | ≤φ400 mm |

| 7.3 | I-Layer insulation roll idayamitha yangaphakathi | φ76 mm |

| 7.4 | Ububanzi be-rolling ye-Layer | 250 ~ 1150 mm |

| 7.5 | De-coil shaft indlela yoxinzelelo | Uhlobo lwe-pneumatic |

| 8. | Iisipheloisixhobo sokukhulula isigqubuthelo |

|

| 8.1 | Ubungakanani | Ekhohlo nasekunene nganye iiseti ezi-4 |

| 8.2 | Isiphelo se-insulation ngaphandle kwedayamitha | ≤φ350 mm |

| 8.3 | Isiphelo se-insulation diameter yangaphakathi | Φ56 mm |

| 8.4 | Ububanzi be-insulation ekupheleni | 10-100mm |

| 9. | Risixhobo sokulungisa (ulungelelwaniso lwefoyile) | Iezizimeleyo iiseti ezi-3 |

| 9.1 | Imo yokulungisa | Inkqubo yombane wefoto |

| 9.2 | Ukulungisa ukuchaneka | Random±0 .4 mm 20 umaleko ikhoyili ±1mm |

| 10. | Inkqubo yolawulo lombane | Imowudi yolawulo oluzenzekelayo ye-PLC |

| 10.1 | Inani ledijithali | 4-digital (0–9999.9) Ukubala ukuchaneka 0.1 jika |

| 10.2 | Ujongano lokusebenza | Umbala wesikrini sokuchukumisa |

| 11. | Okunye |

|

| 11.1 | Isixhobo sokusika i-Layer insulation | Uqwalaselo iiseti ezimbini |

| 11.2 | I-foil impahla imiphetho isixhobo deburring | Uqwalaselo iiseti ezintathu |

| 11.3 | Isixhobo sokucoca izinto zeFoil | Uqwalaselo iiseti ezintathu |

| 11.4 | Ukuwelda itanki lamanzi okupholisa | uqwalaselo |

| 11.5 | Ukunikezwa Amandla | 3-PH,380V/50HZ (Inokwenziwa ngokwezifiso) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com